Assembly Line and Manufacturing Accidents

Working on assembly lines and in manufacturing environments can be very risky business for those employed in these fields. Both can require workers to be around powerful machinery, chemicals, electrical wires, confined spaces, or in other hazardous situations. When proper safety measures are not adhered to, machines can break down and cause injuries. Other risk factors include falling objects, fires, and repetitive-motion injuries.

Working on assembly lines and in manufacturing environments can be very risky business for those employed in these fields. Both can require workers to be around powerful machinery, chemicals, electrical wires, confined spaces, or in other hazardous situations. When proper safety measures are not adhered to, machines can break down and cause injuries. Other risk factors include falling objects, fires, and repetitive-motion injuries.

Types of Injuries

One of the more common types of assembly line injuries is broken and fractured bones. These can happen when a falling object hits the bone or if an employee’s arm, hand, leg or foot gets caught in machinery, body parts may become crushed. Getting hit in the head from an object or machinery could lead to brain trauma, a face, neck and eye injury, or a skull fracture.

Manufacturing plants and other job locations may have dangerous chemicals on site, and these can be contained in battery acid, cleaning solutions, pesticides, and in other materials. Immediate burns can be life-threatening or fatal, and long-term exposure can lead to deadly diseases like mesothelioma and other cancers. Repetitive motion injuries like carpal tunnel syndrome, tendonitis and back strain also take time to develop, and can also lead to significant health problems.

Some workers are also subject to the risk of suffocation, including those who work inside of a confined space such as a tank, a boiler, or a pipe. In these cases, the workers should never work alone; a second, trained employee should be at hand, but out of the space to assist if needed.

More About Injury Prevention

Assembly line and manufacturing personnel should be vigilant about their work environments. Being aware of safety protocols and adhering to them can prevent these types of accidents. It is especially important to be careful around heavy machinery. This applies to those that operate the machinery as well as any others that are nearby.

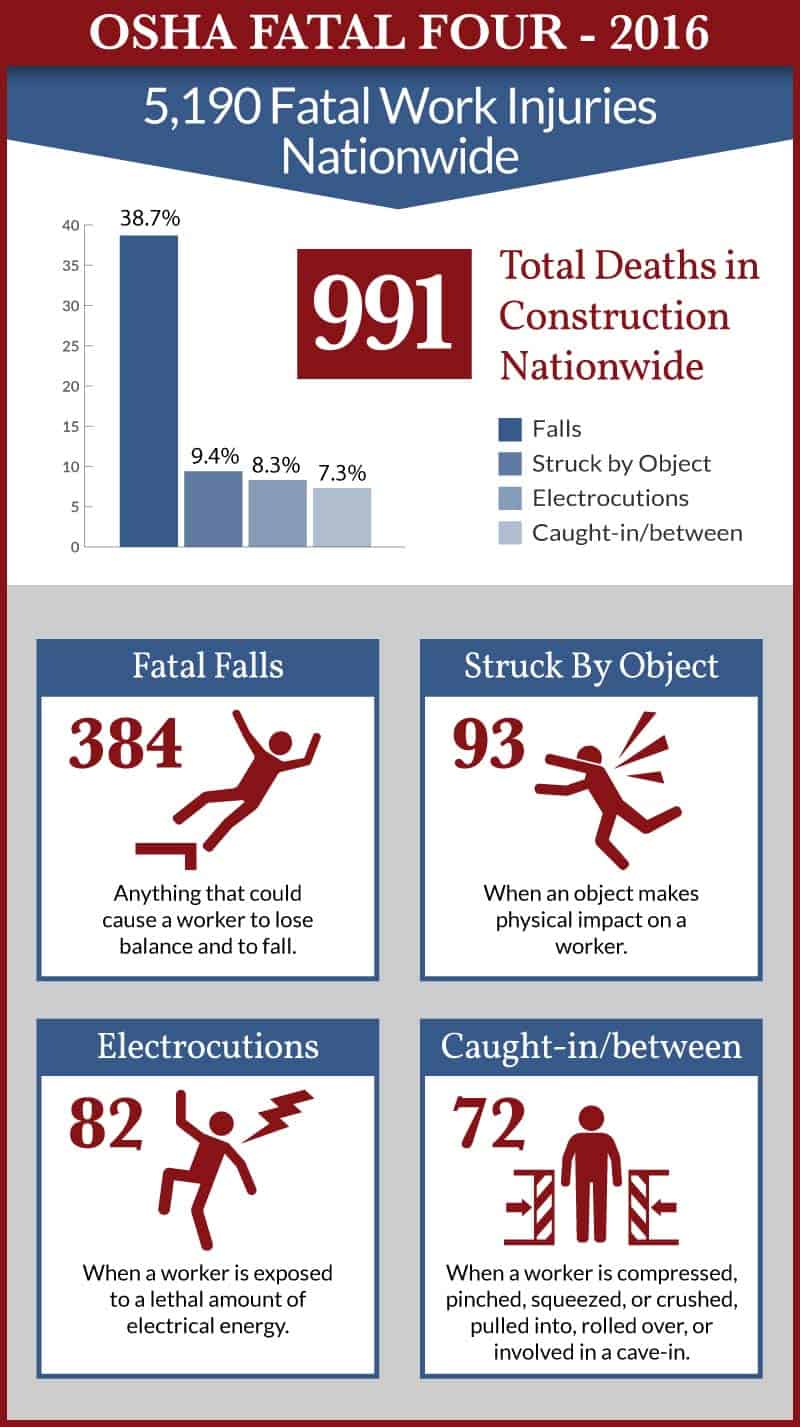

A first step toward promoting safety around the equipment is to ensure that only qualified personnel are in the area. Anyone not trained to work with machinery should keep their distance. This can be enforced by limiting access and posting signs to this effect. All heavy equipment, including factory vehicles, should also be guarded. Safety helmets, goggles, safety harnesses, gloves, and other protective gear should always be used and should conform to Occupational Safety and Health Administration (OSHA) regulations.

Fire prevention at these job sites is also key to preventing work-related accidents. This is done by conducting regular fire inspections and having smoke detectors, fire extinguishers, and fire emergency plans at the ready. To minimize the risk of chemical exposure, all hazardous materials must be labeled, with posted safety instructions nearby. Employees should be trained about chemical exposure symptoms and understand emergency protocol in case of a mishap.

Philadelphia Workers’ Compensation Lawyers at Freedman & Lorry, P.C. Handle Assembly Line and Manufacturing Accident Claims

If you were injured in an assembly line, manufacturing, or any other type of work-related accident, contact a skilled Philadelphia workers’ compensation lawyer at Freedman & Lorry, P.C. Call 888-999-1962 or complete an online form for a free case evaluation. Our offices are in Philadelphia, Cherry Hill, New Jersey, and Pinehurst, North Carolina, and we serve clients in Pennsylvania, South Jersey, and North Carolina.